Before cleaning the surface of the optical filter, the cleanliness of the glass surface must be checked, and the cleaning method should be selected based on this. Commonly used inspection methods are:

1. Contact angle method between optical filter glass surface and liquid

Pour water and ethanol onto the clean optical filter surface, both expand and completely wet, and the contact angle is almost equal to zero. If the glass surface is polluted, water and alcohol cannot be completely wetted, and the contact angle is obvious and large.

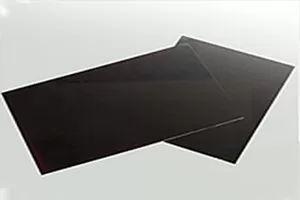

2. The scratch test method of optical filters

Blow clean (filtered) and moist air to the glass surface (breath), and place it in front of a black background. If the glass is clean, a black, thin and uniform moisture film will appear, which is called black marks. If the surface of the optical filter is polluted, the water vapor will condense into uneven water droplets, which are called gray marks.

The water droplets on the gray marks have obvious contact angles, while the contact angles of water in the black marks are close to zero. This is a convenient and effective method commonly used to check the surface cleanliness of optical filters.

3. Static friction coefficient method of optical filter surface

Measuring the coefficient of static friction between solids and glass is a sensitive method for checking the cleanliness of glass surfaces. Clean surfaces have a high coefficient of friction, close to 1. If there is grease or adsorption film on the glass surface, the static friction coefficient will decrease. For example, when the glass absorbs the stearic acid layer, the static friction coefficient is only 0.3.

By measuring the coefficient of static friction of the optical filter surface, the cleanliness of the glass surface can be obtained semi-quantitatively, so that the cleaning effect of various methods can be evaluated.

EN

EN