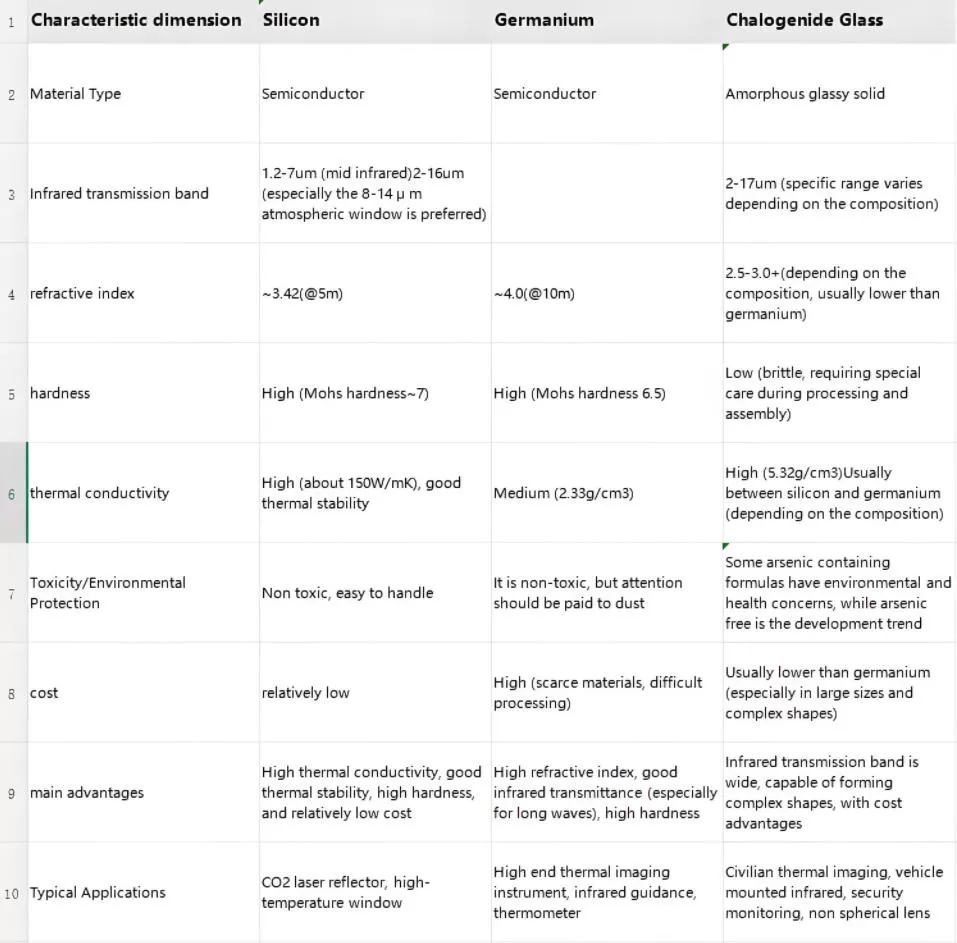

Silicon (Si), germanium (Ge), and sulfur based glass are commonly used mirror materials in infrared optical systems, each with its own characteristics. Summarize the key characteristics of each material itself using the table below:

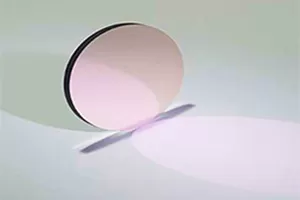

Silicon (Si): Silicon has good transparency in the mid infrared range (1.2-7 μ m), but is opaque to longer wavelengths of infrared light (such as the 8-14 μ m atmospheric window). Its high thermal conductivity and good thermal stability make silicon mirrors very suitable for high-power laser systems (such as CO ₂ lasers) and high-temperature working environments, as heat can dissipate quickly and reduce thermal lensing effects. Silicon has high hardness, good wear resistance and scratch resistance. However, silicon has a relatively low refractive index compared to germanium and may not be the preferred choice in some applications that require extremely high refractive indices.

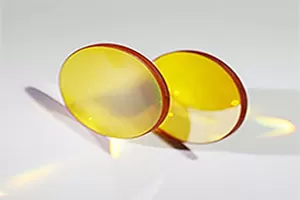

Germanium (Ge): Germanium is a star material in the long wave infrared (LWIR) field, especially in the 8-14 μ m atmospheric window, with very high transmittance. Its extremely high refractive index (~4.0) allows for the design of thinner and lighter optical components, which contributes to system miniaturization. Germanium also has high hardness and can withstand certain harsh environments. But germanium has a higher density, which will increase the weight of the system. Its temperature sensitivity is also high. When the temperature exceeds about 100 ° C, absorption increases and transmittance decreases, so it is usually not used in high-temperature environments. In addition, germanium material is expensive, partly due to its rare crustal content and high extraction costs.

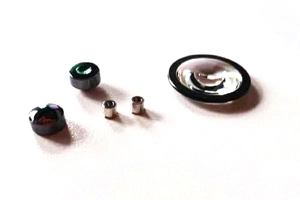

Sulfur based glass: The infrared transmission range of sulfur based glass is usually wide and can be adjusted according to the formula. Many sulfur based glasses have a refractive index lower than germanium, but by adjusting the composition (such as increasing germanium and tellurium content), sulfur based glasses with a refractive index higher than 3 can also be developed. One of its biggest advantages is its strong plasticity, which enables the manufacturing of non spherical lenses and complex shaped optical components through processes such as compression molding, reducing costs and simplifying system structures. However, sulfur based glass usually has lower hardness and is more brittle, so extra care should be taken during processing and assembly to avoid breakage. Some traditional sulfur based glasses contain arsenic (As), and for environmental and health considerations, arsenic free sulfur based glasses are currently one of the research and development directions.

Application scenarios

Due to their different characteristics, these materials are also emphasized in various fields of application:

Silicon reflector: Due to its excellent thermal performance, it is commonly used as a reflector and window for high-power CO ₂ lasers, as well as optical windows in high-temperature industrial environments that require good heat dissipation.

Germanium reflector: mainly used in high-performance long wave infrared systems, such as military thermal imagers, infrared guidance systems, high-end infrared thermometers, and other fields that require extremely high performance.

Sulfur based glass reflector: More commonly used in cost sensitive and complex optical design civilian fields, such as vehicle mounted infrared cameras, security monitoring infrared lenses, smart home sensors, etc. Its ease of being compressed into a non spherical shape also makes it advantageous for simplifying optical systems.

Summary

Simply put, the choice of material mainly depends on specific needs:

Pursuing ultimate long wave infrared performance, high refractive index, with sufficient budget and low operating temperature, germanium (Ge) may be the preferred choice.

Applied in the mid infrared band, high power or high temperature environment, good thermal stability is required → Silicon (Si) deserves special consideration.

Pay attention to cost, require wide infrared transmission bands or complex shaped optical components (such as non spherical surfaces), work in a low temperature environment - sulfur based glass may be more suitable, and pay attention to the development of arsenic free formulations.

EN

EN