In modern optical industries, a spherical lens plays a critical role. Whether used in eyeglasses, cameras, microscopes, or in advanced technologies such as laser systems and astronomical telescopes, a spherical lens is one of the core components of any optical system. This article explores the manufacturing process of a spherical lens and its importance within the optics industry.

Basic Concept of a Spherical Lens

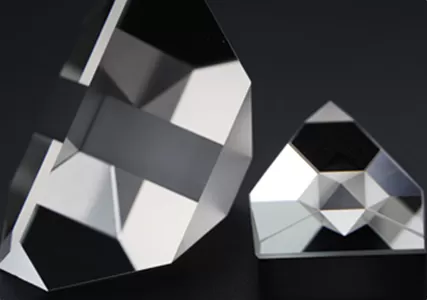

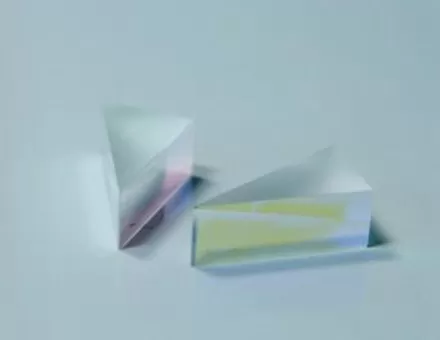

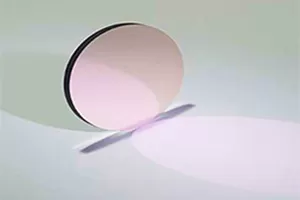

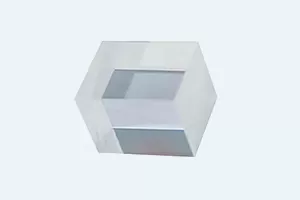

A spherical lens is an optical element with a surface that forms part of a sphere. Based on the curvature, a spherical lens can be classified into convex lenses and concave lenses. A convex lens converges light, while a concave lens diverges it. A spherical lens is widely used in optical systems for focusing, imaging, and aberration correction.

Manufacturing Process of a Spherical Lens

The production of a spherical lens is a highly precise process involving multiple stages, each requiring strict quality control:

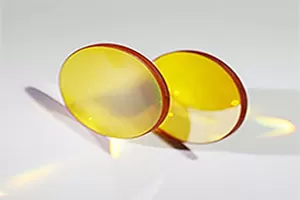

Material Selection

Materials typically include optical glass or optical-grade plastics. Glass offers high transmittance, low dispersion, and excellent thermal stability, while plastic is lighter and easier to process. Material selection depends on the lens's intended application.

Blank Cutting

Large optical materials are cut into rough blanks according to design specifications. This step often uses diamond cutting tools to ensure precision.

Rough and Fine Grinding

Rough grinding shapes the blank close to its final form. Fine grinding further refines the surface, meeting the desired radius of curvature and surface roughness. CNC grinding machines are commonly used to achieve high accuracy.

Polishing

Polishing is one of the most critical steps in producing a spherical lens. It smooths the lens surface to optical quality, reducing scattering and reflection while improving transmittance. Polishing is performed using polishing compounds and pads, either mechanically or manually.

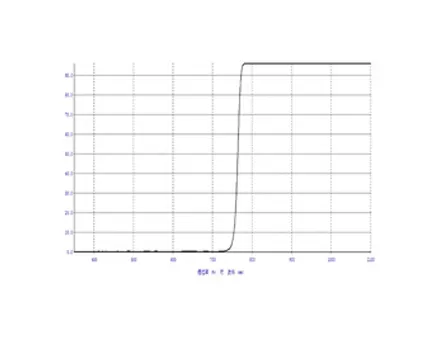

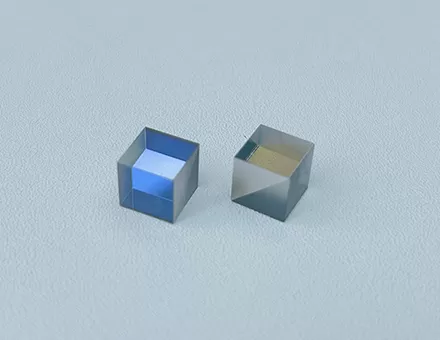

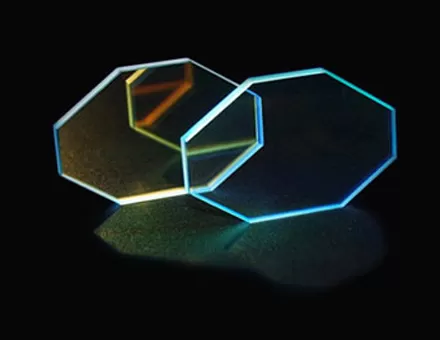

Coating

To enhance optical performance, coatings such as anti-reflective or high-transmittance films are applied to the surface. This is usually done in a vacuum coating chamber to ensure uniformity and strong adhesion.

Inspection and Quality Control

Every lens undergoes rigorous testing before leaving the factory. Parameters such as radius of curvature, surface roughness, transmittance, and aberrations are measured. Only lenses that meet design specifications proceed to the next stage or to shipment.

Importance of Spherical Lens Manufacturers in the Optics Industry

Spherical lens manufacturers represent a core link in the optical supply chain. From consumer electronics and medical devices to aerospace and defense technologies, a spherical lens is indispensable. As optical technologies evolve, the demand for higher precision and performance grows. Therefore, the innovation and manufacturing capabilities of spherical lens manufacturers directly affect the quality and competitiveness of optical products.

Consumer Electronics

In smartphones, cameras, and VR/AR devices, a spherical lens is used for imaging, focusing, and aberration correction. With increasing demands for image quality, manufacturers must continuously improve precision and optical performance.

Medical Devices

In the medical field, a spherical lens is widely used in endoscopes, microscopes, and laser surgery equipment. High-precision lenses enhance imaging quality and therapeutic accuracy, contributing to better patient outcomes.

Aerospace and Defense

In aerospace and defense, a spherical lens is used in telescopes, LiDAR systems, and missile guidance technologies. These applications demand extreme precision, durability, and environmental resistance—requiring manufacturers to have advanced technology and strict quality control systems.

As a key component of optical manufacturing, the technical expertise and production capacity of spherical lens manufacturers directly determine the performance and quality of optical products. With ongoing advancements in optical technology, manufacturers will continue to push the boundaries of innovation and process refinement—delivering higher-quality optical solutions across diverse industries. Whether in consumer electronics, medical devices, or aerospace and defense, a spherical lens will remain an irreplaceable element, driving the future of optical development.

EN

EN