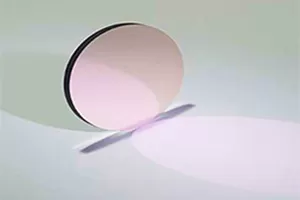

Cylindrical mirror is a special optical component, and its working principle and application scenarios are significantly different from traditional spherical mirrors. The following is a detailed explanation of its core principles and main applications:

Ⅰ. Working principle of cylindrical mirror

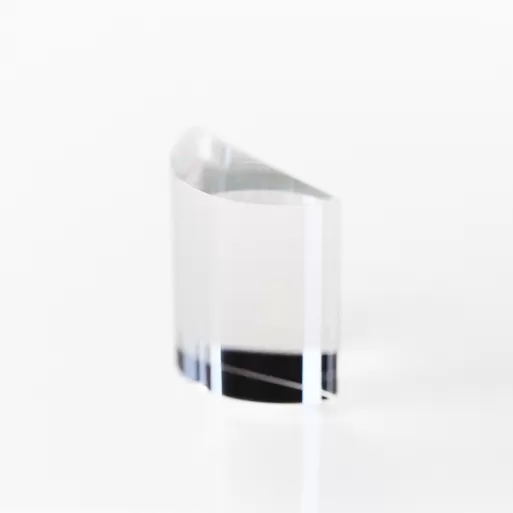

The core feature of a cylindrical mirror is its surface shape: one direction is a cylindrical surface (with curvature), and the other vertical direction is a plane (without curvature). This asymmetric structure results in completely different behaviors of light rays in two orthogonal directions:

1. Curvature direction (meridian direction)

-Convex cylindrical mirror: When parallel light is incident, it will focus into a focal line (rather than a point), similar to compressing light into a line.

-Concave cylindrical mirror: The light emitted by a point light source is diverged into parallel light bands.

-Principle: Following the law of refraction (Snell's law), light rays in the direction of curvature are deflected, and the focal length is determined by the radius of curvature and the refractive index of the material.

2. Plane direction (sagittal direction)

-When light passes through a plane, it does not deviate (equivalent to passing through a flat glass), and does not change the convergence or divergence state of the light.

3. Imaging characteristics

-Point light source → imaging as a straight line (line focus);

-Circular spot → deformable into elliptical or linear spot;

-Introducing significant astigmatism: focal separation between the meridional and sagittal planes.

Ⅱ. Core application areas

The unidirectional optical manipulation capability of cylindrical mirrors makes them irreplaceable in the following fields:

1. Laser processing and manufacturing

-Laser cutting/marking: Compressing a circular laser beam into a slender line spot (increasing energy density), used for precision processing of glass, silicon wafers, and metals.

-Surface treatment: Generate uniform linear light spots for laser quenching, cladding, and annealing.

-Beam shaping: Combining multiple cylindrical mirrors to convert Gaussian beams into flat line light spots, improving processing uniformity.

2. Optical imaging and detection

-Line scanning imaging system:

-The cylindrical mirror collimates the light source into a linear illumination, which is used in conjunction with a linear array camera to scan objects at high speed (such as product inspection on assembly lines and anti-counterfeiting of banknotes).

-Applications: LCD panel defect detection, print quality monitoring, document scanner.

-3D sensing: Generating linear laser patterns in structured light projection.

3. Display and Lighting Technology

-Laser projector: shaping the elliptical light spot emitted by the laser diode into rectangular uniform light.

-Laser display: combined with a micro lens array to optimize the light field distribution.

-Barcode scanning: Rotating cylindrical mirrors generate scanning lines that cover the barcode area (traditional laser scanning guns).

4. Biomedical and scientific instruments

-Flow cytometer: Focus the laser into thin sheet light (~10 μm thick) and irradiate the flowing cells to excite fluorescence.

-Confocal microscope: Generate line focus scanning samples to improve imaging speed.

-Optical coherence tomography (OCT): Line illumination mode reduces motion artifacts.

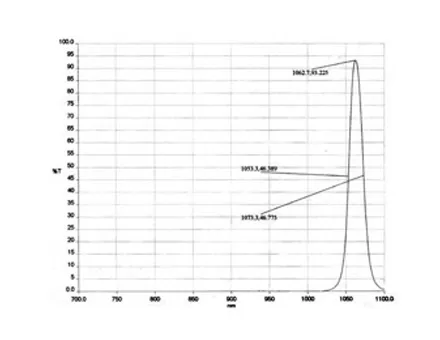

5. Spectroscopy and Optical Systems

-Spectrometer: collimated slit light source or focused dispersion light to detector (such as concave grating spectrometer).

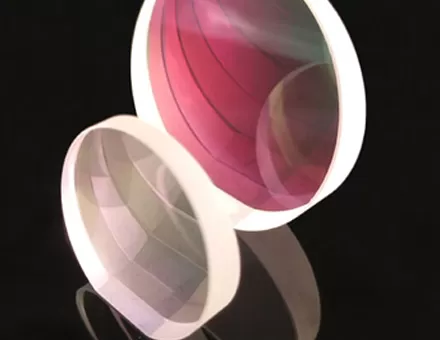

-Astigmatism correction: Compensate for the astigmatism introduced by spherical lenses (reverse cylindrical mirrors counteract distortion).

Ⅲ.Key design points- Parameters and Description

-Direction alignment: The curvature direction must strictly match the application requirements (such as laser cutting that needs to be perpendicular to the material surface).

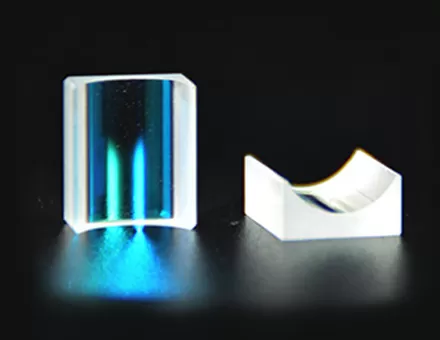

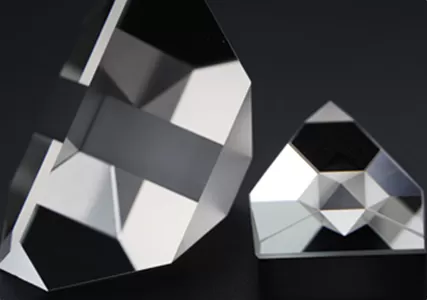

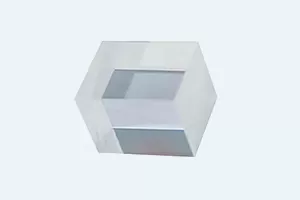

-Combination use: Two cylindrical mirrors placed orthogonally can independently control the X/Y direction optical path (e.g. laser beam expansion+focusing).

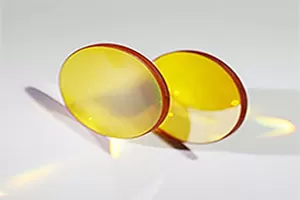

-Material selection: fused silica for ultraviolet application, silicon/germanium for infrared application, and BK7 glass for visible application.

-Coating requirements: anti reflective film (reducing reflection loss), high reflectivity film (reflective cylindrical mirror), or metal film (laser high-power tolerance).

-Aberration management: It is necessary to optimize curvature or use non spherical cylindrical mirrors to reduce astigmatism, and high-precision systems require a combination of spherical mirror correction.

Summarize

Cylindrical mirrors, with their unidirectional optical manipulation capability, are irreplaceable in scenes where light energy needs to be compressed into a linear distribution. From industrial laser processing to biomedical imaging, and then to consumer electronics (scanners, projectors), its core value lies in:

1. Efficient beam shaping (circle → line/ellipse);

2. One dimensional high-resolution manipulation (line scanning/line illumination);

3. System integration flexibility (orthogonal combination to achieve complex optical paths).

The correct selection of curvature direction, focal length, and coating scheme is the key to maximizing its performance.

EN

EN