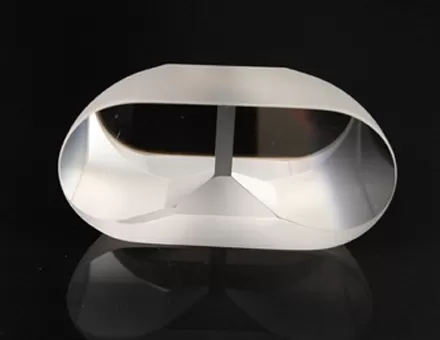

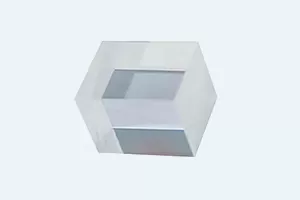

In laser processing, machine vision, and 3D sensing, transforming a laser beam into a uniform line spot is critical for system performance. The Powell Lens, with its unique beam-shaping capability, has become the ideal solution for industrial line laser generation.

Laser Processing & Industrial Manufacturing

(1)Laser Cutting/Welding

Application: Converts Gaussian beams into uniform line lasers for consistent processing.

Advantages:Intensity uniformity >90%, avoiding uneven cutting edges.

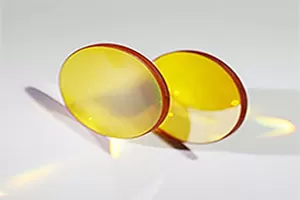

Supports high power (up to 500W with ZnSe material).

(2)Laser Marking

Optical Measurement & Sensing

(1)3D Structured Light Scanning

(2)LiDAR

Biomedicine & Research

(1)Flow Cytometry

Application: Excites fluorescent labels with linear spots to reduce cell-counting errors.

Specs: UV-grade (355nm) fused silica lens, >99% transmittance.

(2)Confocal Microscopy

Application: Line-scan imaging, 10x faster than point scanning.

Consumer Electronics & Display

(1)AR/VR Optical Modules

(2)Laser TV

Application: Speckle reduction for uniform DMD chip illumination.

Future Trends

Freeform Powell Lenses: For non-linear scans (e.g., curved lines).

MEMS Integration: Dynamic line length adjustment (patented).

Conclusion

From micron-scale cell analysis to kilometer-range LiDAR, the Powell Lens enables “high uniformity, low distortion” beam shaping, making it the “beam magician” of modern optoelectronics.

EN

EN