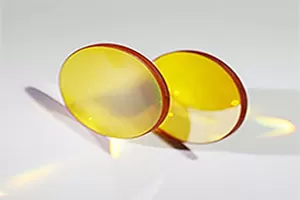

Plano concave lenses are common optical elements widely used in laser technology, imaging, medical equipment, and telecommunications. As critical components in optical systems, the manufacturing quality of plano concave lenses directly affects overall system performance. This article provides an in-depth exploration of their manufacturing processes, technical highlights, and key factors to consider when selecting a plano concave lens manufacturer.

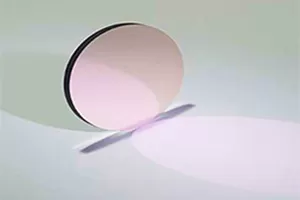

Fundamental Characteristics of Plano Concave Lenses

A plano concave lens features one flat surface and one concave surface. These lenses are characterized by a negative focal length and the ability to diverge light rays. The primary functions of plano concave lenses include beam expansion, optical path correction, and focal length adjustment in optical systems. Due to their unique optical properties, plano concave lenses play essential roles in devices such as lasers, telescopes, and microscopes.

Manufacturing Process of Plano Concave Lenses

Material Selection

Plano concave lenses are typically made from optical glass or crystals such as BK7, fused silica, or calcium fluoride. The choice of material depends on the application scenario—for example, in laser systems, materials with high transmittance and low absorption are preferred.

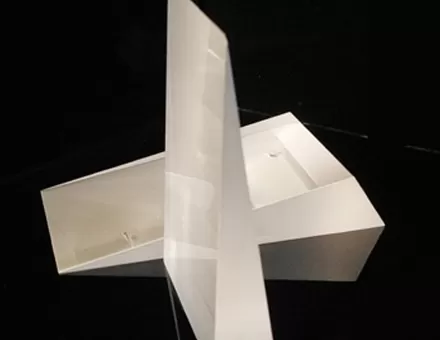

Precision Machining

The production process includes cutting, grinding, polishing, and coating. Grinding and polishing are key steps that directly influence surface quality and optical performance. Modern manufacturing makes use of computer numerical control (CNC) machines to ensure geometrical accuracy at the micron level.

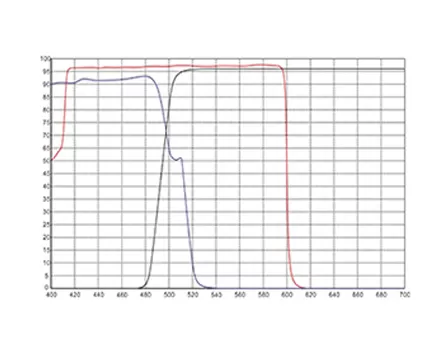

Coating Technology

To enhance transmission and reduce reflection, manufacturers apply anti-reflective coatings to the lens surface. Coating techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) effectively minimize optical loss and improve system efficiency.

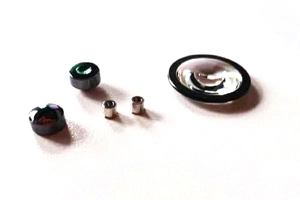

Quality Inspection

After production, plano concave lenses undergo rigorous inspection. Critical parameters such as surface roughness, radius of curvature, focal length, and optical uniformity are measured. Advanced tools like interferometers and profilometers ensure every lens meets the required specifications.

Application Fields of Plano Concave Lenses

Laser Technology

In laser systems, plano concave lenses are used for beam expansion and collimation, helping to maintain laser stability and achieve accurate focus.

Imaging Systems

In microscopes and telescopes, plano concave lenses correct optical paths and enhance image quality.

Medical Devices

In medical laser instruments and endoscopes, plano concave lenses are used to control and focus beams, ensuring operational precision and safety.

Communication Technology

In fiber optic communication systems, plano concave lenses are used for coupling and separating optical signals, improving data transmission efficiency.

How to Choose a Plano Concave Lens Manufacturer?

Technical Capability

Select a manufacturer with advanced equipment and extensive experience to guarantee high-precision, high-performance lens production.

Quality Control

A reliable manufacturer should have a comprehensive quality control system and be able to provide detailed inspection reports and certification documents.

Customization Services

The ability to offer customized solutions—such as special materials, non-standard sizes, or specific coating requirements—is an important consideration.

After-Sales Support

Responsive technical support, maintenance services, and fast customer response are critical factors in choosing a supplier.

As key components in optical systems, plano concave lenses require high-quality production and strict quality control. Partnering with an experienced manufacturer like Ecoptik—known for its technical strength, rigorous standards, and outstanding service—ensures reliable performance and optimal application results. As optical technologies continue to evolve, the manufacturing techniques and application scope of plano concave lenses will further expand, offering more precise and efficient optical solutions across diverse industries.

EN

EN