Preface and Standard Background

ISO 10110 stands for "Optics and optical instruments - Preparation of drawings for optical elements and systems".

Its purpose is to provide a unified, precise, and unambiguous "language" or symbol system for designers, optical manufacturers, and inspectors to annotate information such as materials, deviations, tolerances, defects, surface quality, coating requirements, etc. on optical drawings (design drawings).

Using the ISO 10110 standard can reduce manufacturing misunderstandings, inspection disputes, and ensure continuity from design to manufacturing and acceptance.

The ISO 10110 standard is actually a series (multiple parts, Part 1, Part 2,..., etc.), each part specifying the labeling method for a certain category of "optical properties+allowable tolerances/limits".

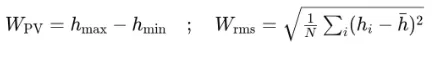

In many industries, this standard is referenced when designing and manufacturing optical components such as lenses, prisms, windows, lenses, etc., to ensure consistent understanding of the labeled content.

Overview of the Structure and Parts of ISO 10110

The following are the main parts included in ISO 10110, along with a rough classification of their contents

Part 1 General Provisions/General Rules for Optical Patterns Layout, Projection Method, Labeling Language, Testing Area, Dimensional Units, etc. are the basic parts, and each drawing must comply with their regulations

Part 2 Material Defects - Stress Birefringence "0/X" annotation, where X represents the maximum allowable refractive difference (unit: nm/cm) to illustrate the phase difference deviation caused by residual stress that may occur when light propagates in the material

Part 3 Material Defects - Bubbles/Inclusions "in the form of" 1/N × A ", where N=quantity and A=area or size indicating how many bubbles/inclusions are allowed to exist in a certain area, and specifying the maximum size limit

Part 4 Material Defects - Inhomogeneity&Striae "The symbol" 2/... "is used to indicate the degree of non-uniformity limitation of the material in terms of refractive index, density, refractive index gradient, etc

Part 5 Surface Form Tolerances "3/A (B/C)" or other forms specify the tolerance methods and annotation methods for optical surface shape errors (such as deviation from ideal spherical or non spherical surfaces)

Part 6 Centring tolerances "4/..." annotation is used to describe the allowable range of axis deviation, inclination, eccentricity, etc. between two surfaces or axes

Part 7 Surface Defects/Scratches/Pits "5/..." Mark allowed scratch/dig and other defect specifications, including quantity, size, distribution, etc

Part 8 Surface texture symbol similar to "8/..." is used to specify micro roughness, ripples, etc. (usually meaningful in non imaging or less strict optical systems)

Part 9 Surface treatment and coating "9/..." describes the requirements and labeling methods for optical coatings (reflective, transmissive, obstructive, etc.) or surface treatments (scratch resistant, hardening, etc.)

Part 10 Table for lens data representation of optical components/combination components is presented in a tabular format

In depth explanation of several key clauses (for ease of understanding/application)

Below are a few commonly used and slightly complex parts in optical design and manufacturing for further explanation.

1. General Principles of Drawings (Part 1)

Projection method: ISO 10110 typically specifies the use of first angle projection, which is different from the commonly used third angle projection in the United States.

Units and symbols:

-The length dimensions are generally measured in metric units (millimeters, meters, etc.). If imperial units are to be used, they must be indicated on the drawing.

-When representing decimals in ISO, use commas (,) instead of dots (.) as decimal symbols.

Test area/effective surface: Not the entire surface of the optical component needs to meet the requirements. Usually, a "effective diameter" or "measurement area" (such as the effective diameter represented by "Ø e") is marked to limit the tolerance or performance requirements to only take effect within that area.

Benchmark/reference line/axis:

-The centerline and the optical axis/path axis (which may be the same or different) need to be marked differently in the drawing.

-On optical drawings, "dash dot" or "dash dot dot dot" lines are commonly used to represent different types of axes or optical paths.

Although this section does not directly involve optical performance tolerances, it is the foundation of the entire ISO 10110- any specific tolerance, defect, coating, or other marking must be reflected in the drawing format that complies with the provisions of Part 1.

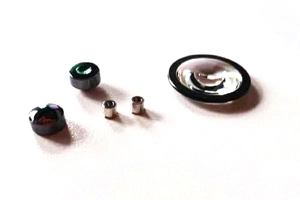

2. Surface Shape Tolerance - Part 5

This is a crucial part in actual manufacturing and inspection, as it determines the allowable degree of deviation of optical surfaces from ideal shapes such as ideal spheres, free-form surfaces, etc.

In ISO 10110-5:2015, it is emphasized to use nanometers (nm) as the tolerance unit, rather than just using interference fringe units. If using stripe units, the reference wavelength must be clearly indicated.

The annotation method is usually in the format of "3/A (B/C)":

-A is the allowable value for spherical deviation (maximum spherical deviation, spherical arc deviation)

-B is the maximum asymmetric error (Peak to Valley, irregular error of PV)

-C is the residual error of axial symmetry (such as symmetry deviation or fitting error)

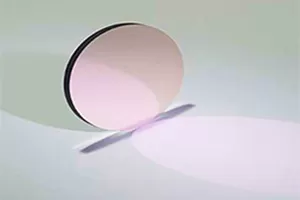

What is the peak to valley height difference?

Peak to Valley Error (P-V)

It is the height difference between the highest and lowest points on this' hill '.

For example:

Ideal hill (design surface): The height should be 100.000 mm.

After actual processing: a certain highest point=100.001 mm; a certain lowest point=99.999 mm;

So peak valley difference (PV)=0.002 mm=2 µ m.

This means that the mirror surface fluctuates by 2 microns compared to the ideal shape.

In optics, we do not use 'micrometers', but' wavelength λ 'to represent it.

If the test light is 632.8 nm, then: 2 µ m ≈ 3.16 λ

Tolerance can also be given in the form of slope deviation, with units such as mrad, μ rad, arcminutes, arcseconds, etc.

In addition, if no shape tolerance is specified for a surface, it may be referred to other standards (such as the default values in ISO 10110-11) for processing.

Overall, Part 5 clarifies the "acceptable deviation" between the design intent (ideal shape) and the actual manufacturability.

3. Surface defects/scratches/dents - Part 7

Surface defects are an important quality control indicator in the manufacturing process of optical components, especially imaging, lasers, and precision instruments.

ISO 10110-7 (revised in 2017) defines two main defect control methods: visibility specification and dimensional specification.

Dimensional specification: It is usually expressed in the form of "5/N × A", where N is the allowed number of defects and A is the defect size (e.g. expressed in area or line width). If scratches, coating defects, edge chips, etc. are still allowed on the component, additional symbols such as "L N × A" or "C N ′ × A ′" can be used to indicate them.

Visibility specification: Similar to some military/traditional standards (such as MIL-PRF-13830B) that use microscopes or visual comparisons to determine the brightness or visibility of scratches/defects. ISO 10110-7 takes into account such methods in permissible ways.

In addition, to make the expression more objective, ISO 10110-7 introduces a method for numerically and dimensionally evaluating defects, which can be used in conjunction with ISO 14997 for inspection and characterization.

In actual production, this indicator often directly affects the yield, cost, and performance of finished products (especially in high-power lasers, astronomical lenses, and microscope systems).

4. Laser damage threshold - Part 17

For high-power laser systems or optical components that require high energy density irradiation, the ability to resist laser damage is crucial.

In ISO 10110-17, the allowed laser irradiation thresholds (such as unit energy density, power density, pulse energy, etc.) and conditions (wavelength, pulse width, repetition rate, etc.) are marked with the symbol "6/...".

The purpose of doing so is to clarify in the design drawings which level of power density or lower devices must be safe and undamaged, so as to have clear goals in material selection, coating, cleaning, process control, and other aspects.

Basic symbol system in ISO 10110

1. Basic symbols

N/... "n" is the identification number of each part of ISO 10110 (from 0 to 19, etc.). Write specific parameters on the right side. For example: 5/A, 3/0.2 (0.05/0.01), followed by the parameters or values specified in this section.

Ø represents the diameter, such as Ø 50 mm used for the outer diameter and effective aperture of optical components.

E represents the effective aperture, such as Ø e=40 mm, which refers to the effective area for inspection or performance assurance.

The wavelength of λ light, such as λ=632.8 nm, is commonly used in interferometry or wavefront tolerance.

PV peak to valley value, such as PV=λ/10, represents the maximum peak to valley difference of morphology deviation.

Root Mean Square error of rms, such as σ=λ/20, represents the statistical mean error of the surface or wavefront.

Δ n refractive index difference, such as Δ n ≤ 1 × 10 ⁻⁶, is common in material non-uniformity.

The non-uniformity level of Δ N, such as Δ N=3, is usually classified according to standard levels.

The surface inclination or eccentricity of δ, such as: δ ≤ 1 mrad, has a center error.

2. Materials and Internal Defects (Parts 2-4)

(1) Stress birefringence (Part 2)

Annotation format: 0/N, where N represents the maximum allowable phase difference (nm/cm).

Basic formula:

Δφ = C ·t

Δ φ: Phase difference caused by stress birefringence (nm)

C: Material stress optical constant (nm/cm · MPa)

t: Thickness (cm)

Example: 0/10 → Maximum allowable stress birefringence of 10 nm/cm.

(2) Bubbles and inclusions (Part 3)

Annotation format:

1/N×A

N: Maximum allowable quantity

A: Maximum size or area (mm ² or mm)

Explanation:

Indicate the allowable number and size limit of bubbles or inclusions within the entire component.

Example: 1/3 × 0.1 → Allow 3 bubbles, each with a diameter ≤ 0.1 mm.

(3) Non uniformity and stripes (Part 4)

Annotation format: 2/N

Where N is the grade number (1-5), the lower the grade, the more uniform the material.

Related formulas:

Δn = nmax - nmin

The level corresponds approximately to Δ n:

Remarks on upper limit of refractive index difference

1 ≤ 1 × 10 ⁻⁶ extremely high uniformity

3 ≤ 3 × 10 ⁻⁶ for general precision optics

5 ≤ 1 × 10 ⁻⁵ Loose requirement

3. Surface shape and alignment (Parts 5-6)

(1) Surface Shape Tolerance (Part 5)

Common annotation formats:

3/A(B/C)

meaning:

A: Spherical deviation

B: Asymmetric error (irregularity)

C: Residual symmetry error or reference shape deviation

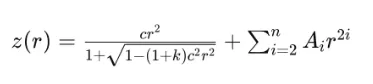

Typical formula:

PV = h {max}- h{min}

Example:

3/0.2 (0.05/0.01) → Total shape deviation ≤ 0.2 µ m, irregular error ≤ 0.05 µ m, residual error ≤ 0.01 µ m.

(2) Alignment tolerance (Part 6)

Annotation format:

4/Δθ; Δx

Δ θ: inclination angle deviation Δ x: eccentric displacement

Formula definition:

Δx = r · Δθ

Example: 4/0.5 mrad; 10 µ m → Allow tilt of 0.5 mrad and eccentricity of 10 µ m.

4. Surface defects and roughness (Parts 7-8)

(1) Surface Defects (Part 7)

Annotation format: 5/N × A

N: Allowable defect quantity A: maximum size (mm)

Empirical formula: If expressed in terms of area ratio:

R = Adefects÷Aeffective×100%

Example: 5/2 × 0.025 → Allow 2 defects with a diameter ≤ 0.025 mm.

(2) Surface roughness (Part 8)

Annotation format: 8/Ra

Ra: arithmetic mean roughness

Example: 8/0.005 → Surface roughness Ra ≤ 0.005 µ m.

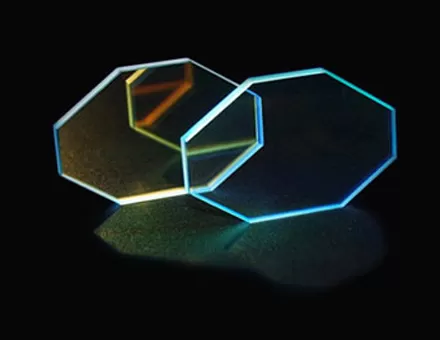

5. Coating and Laser Threshold (Parts 9&17)

(1) Coating (Part 9)

Annotation format: 9/Type; R/T; λ

Type: Coating type (AR, HR, BS, etc.)

R/T: Reflectance or Transmittance Requirements

λ: Reference wavelength

Example:

9/AR; R<0.5%; λ=550 nm → Anti reflective coating, reflectivity<0.5% at 550 nm.

(2) Laser damage threshold (Part 17)

Annotation format: 6/E (L, τ)

E: Energy density (J/cm ²)

L: Wavelength (nm)

τ: Pulse width (ns)

Formula:

Fthreshold = Edamage÷A

A: Illumination area

Example: 6/5 (1064, 10 ns) → Damage threshold ≥ 5 J/cm ² under 1064 nm, 10 ns pulse.

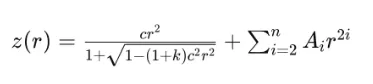

6. Wavefront and Non spherical Surface (Parts 12&14)

(1) Non spherical (Part 12)

Standard equation:

C=1/R: curvature

K: Conic constant

Ai: Higher order coefficient

Example annotation: 12/c=0.02; k=-1; A4=1×10⁻⁶

7. Wavefront Error (Part 14)

Wavefront RMS/PV expression:

14/WPV(Wrms); λ

Example: 14/λ/10 (λ/20); λ=633 nm

8. Provide a complete annotation example (integration)

Assuming that the ISO 10110 label of a certain lens sheet is as follows:

Ø50 × 5 mm N-BK7

0/10 1/3×0.1 2/3 3/0.2(0.05/0.01) 4/0.5 mrad 5/2×0.025 8/0.005 9/AR; R<0.5%; λ=550 nm

Interpretation:

Diameter 50 mm, thickness 5 mm, material N-BK7

Birefringence ≤ 10 nm/cm

Bubbles ≤ 3, each ≤ 0.1 mm

Non uniformity level 3

Surface shape error 0.2 µ m, total irregularity 0.05 µ m, residual 0.01 µ m

Mean square error ≤ 0.5 mrad

Surface defects ≤ 2 (≤ 0.025 mm)

Roughness Ra ≤ 0.005 µ m

Surface anti reflective coating (reflectivity<0.5% at 550 nm)

Comparison and Precautions between ISO 10110 and Other Standards/Practical Applications

1. Comparison with MIL/Military Standards

ISO 10110 is more quantitative and explicit in surface defect labeling than traditional MILs (such as MIL-PRF-13830B), thereby reducing human visual judgment errors.

In some cases, the "5/N × A" style of ISO 10110 can be used to express a certain correspondence with MIL's "scratch dig" level (but not a direct 1:1 conversion).

2. Standard version/update issues

For design and manufacturing personnel, it is important to confirm which version (or whether there are alternative national/regional standards such as GB, GOST, etc.) your country/institution is using and follow the same version, otherwise labeling may result in interpretation bias.

3. Annotation and Communication in Practice

ISO 10110 uses a large number of symbols, codes, and abbreviations, which are often difficult for beginners to master. In practice, optical drawings are often accompanied by annotations, explanatory notes, or "decoding tables" to assist understanding.

Sometimes designers may moderately simplify annotations (omitting certain redundant symbols), provided that both the manufacturing and acceptance parties are aware of the simplification agreement.

Manufacturers/acceptance parties should communicate with designers to confirm if there are any ambiguous or unmarked areas when seeing ISO 10110 markings.

4. Standards cannot replace performance design

ISO 10110 is a labeling standard that tells manufacturing and acceptance how to "write/read/inspect", but it cannot tell you exactly how good the tolerance/defect level of an optical system should be to achieve performance indicators (such as MTF, imaging quality, etc.). In system design, it is also necessary to select appropriate tolerance levels based on optical simulation/tolerance analysis, and then write these levels in accordance with ISO 10110 specifications on the drawings.

Summary (Why ISO 10110 is Important)

It provides a standardized "language" between optical design, manufacturing, and inspection, reducing errors or disputes caused by different understandings of terms/symbols.

It covers almost all aspects of optical components that may be of concern, including material defects, surface shape deviations, alignment accuracy, surface defects, coating/treatment, and laser damage capabilities.

In practical engineering, the correct use of ISO 10110 labeling can make the design, manufacturing, and inspection of optical components smoother, more reliable, and more convincing.

EN

EN