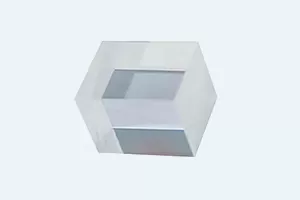

Ⅰ. Mold material and processing of optical glass prism

The mold material needs to have the following characteristics.

1. The surface is free from defects and can be ground into a smooth optical mirror surface without pores.

2. It has high oxidation resistance under high-temperature environmental conditions, and the structure does not change, the surface quality is stable, and the surface accuracy and smoothness remain unchanged.

3. It does not react with the glass or cause adhesion and has good demoulding performance.

4. It has high hardness and strength under high-temperature conditions.

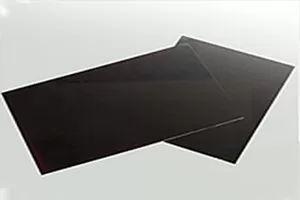

There are many patents related to the development of mold materials. The most representative mold materials are super-hard alloy as the substrate, coated with precious metal alloys and titanium nitride films on the surface. Silicon carbide and super-hard alloy as the substrate, the surface is coated with hard carbon, diamond-like carbon, and other carbon-based films and Cr2O-ZrO2-TiO2 series new ceramics.

The mold materials used for optical glass prism molding are generally hard and brittle. To precisely process these mold materials into molds, high-rigidity and high-resolution ultra-precision computer digital control with a resolution of 0.01μm or less must be used. The processing machine tool uses diamond grinding wheels for grinding. Grinding can obtain the desired shape accuracy, but then it needs to be polished and finished into an optical mirror surface. In high-precision aspheric surface processing, the test and evaluation technology of the aspheric surface shape is very important. The processing requirements for micro-prism profiling molds are more stringent, and the precision must be further improved and the traces of grinding must be reduced.

Ⅱ. Application of optical glass prism molding technology

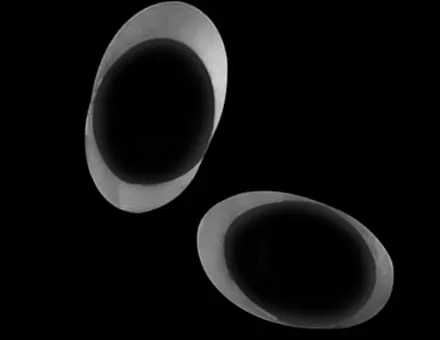

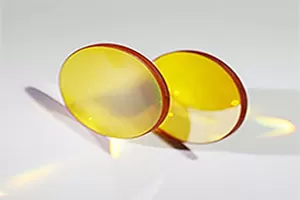

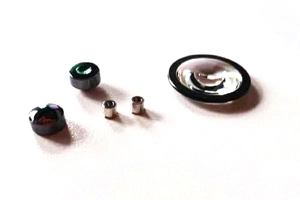

At present, optical glass prism molding technology has been used for the mass production of precision spherical and aspheric lenses. Usually, in addition to the general production of lenses with a diameter of about 15mm, it can also produce large-diameter lenses with a diameter of 50mm, micro-lens arrays, and so on. It is now possible to manufacture microlens arrays with a diameter of 100 μm per lens.

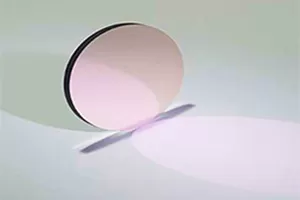

1. Manufacturing spherical and aspheric optical parts used in military and civilian optical instruments, such as lenses, prisms, and filters.

2. Manufacturing aspheric lenses for optical fiber couplers for optical communications.

3. Concentrating aspheric lens for optical discs: one aspherical lens manufactured by compression molding method can replace the three spherical lenses used in the optical lens of an optical disc reader. Due to the high precision of the molded aspheric lens, it can not only control and correct the axial aberration of the large numerical aperture but also reduce the weight and cost of the original small lens by 30-50%.

4. It can produce aspheric lenses for camera viewfinders, aspheric lenses for film projectors and camera lenses, and so on.

EN

EN