Ⅰ. Influence of the direction of the custom optical filters on the wavelength

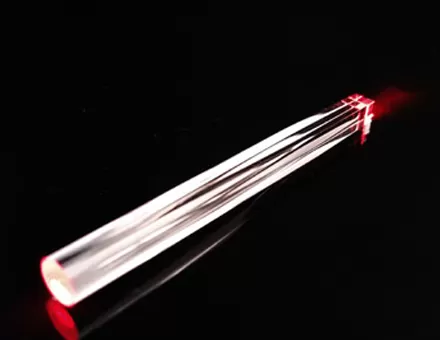

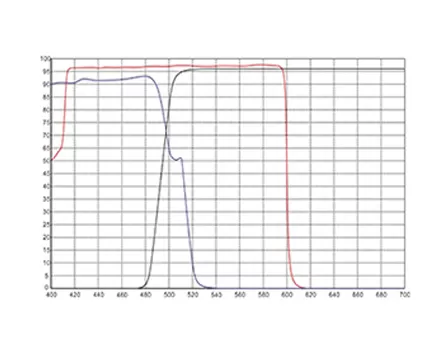

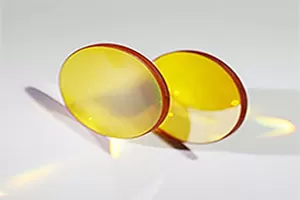

The edge of the optical filter is engraved with an arrow to indicate the recommended direction of the light transmission filter. Although any side of the custom optical filters can filter towards the light source, it is better to turn the coating side towards the light source. This can minimize the thermal effect or possible thermal damage caused by the radiation outside the passband absorbed by the cut-off substrate or colored glass filter layer. The curve of the measured transmittance of the optical filter as a function of wavelength under the illumination of the low-intensity broadband light source. The results show that the direction of the transmission filter has little effect on the intensity and spectrum of the emitted light. The minimum difference between the incidence of light from the front and back is likely to be caused by small changes in the incidence angle when the custom optical filters are moved, flipped, and replaced.

More and more people are choosing custom optical filters, which can satisfy personal demands. When noncollimated light or light is not incident vertically on the optical filter surface, the central wavelength (the wavelength corresponding to the transmittance peak) will move to the short wavelength, and the shape of the transmission band (passband) will change. By changing the incident angle slightly, the passband of the optical filter can be effectively adjusted in a small range. When the incident angle changes significantly, the central wavelength will vary greatly, and the shape of the passband will be distorted, and even the passband transmittance will be significantly reduced.

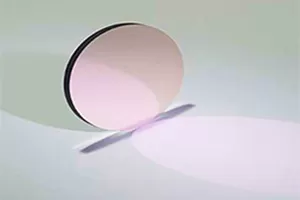

Ⅱ. Effect of temperature of custom optical filters on wavelength

By changing the temperature of the custom optical filters, the central wavelength of the band-pass optical density filter can be fine-tuned (about 1 nm in the working range of the optical filter). This is mainly caused by slight thermal expansion or contraction of the film.

As one of the best optical component companies, Ecootik was founded in 2004 and is located in Changchun, a Chinese optical base with beautiful scenery and profound visual culture. We have the most advanced modern technology machines for manufacturing and testing all kinds of precision optical devices.

Our company covers an area of 2000 square meters and is supported by 120 workers. If you have a demand for our products, you can contact us online!

EN

EN