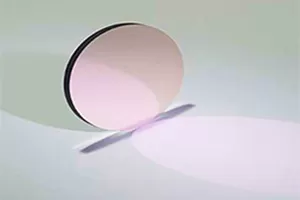

In modern optical systems, the plano convex lens serves as a fundamental and vital optical component. It is widely used in laser focusing, imaging systems, lighting equipment, and various precision instruments. Featuring one flat surface and one convex surface, the plano convex lens has a simple design but powerful functionality, capable of efficiently focusing or collimating light. With the continuous advancement of optical technology, the demand for the custom convex lens is growing rapidly. This article introduces the customization process and applications of the plano convex lens in detail.

Basic Characteristics of the Plano Convex Lens

The main function of a plano convex lens is to focus parallel light rays onto a focal point or to convert light from a point source into a parallel beam. Its optical performance is primarily determined by the following parameters:

Radius of Curvature (R): The curvature radius of the convex surface determines the focal length and focusing power. A smaller radius results in a shorter focal length and stronger focusing ability.

Focal Length (f): The focal length is the distance over which parallel rays are brought to focus after passing through the lens. It is related to the radius of curvature and the refractive index of the lens material.

Diameter (D): The diameter affects the aperture size, influencing both the amount of light collected and the beam size.

Material: The lens is typically made from optical glass or optical-grade plastic. Different materials have different refractive indices and dispersion properties, which impact the lens's optical performance.

Customization Needs for the Plano Convex Lens

Special Focal Length: Some applications require a specific focal length that standard lenses cannot provide. By adjusting the radius of curvature and material, a custom convex lens can be designed to meet exact specifications.

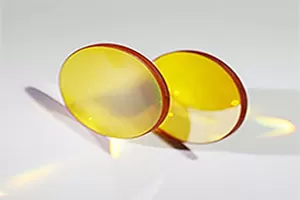

Special Materials: In certain environments—such as high temperature, high radiation, or chemically corrosive settings—standard optical materials may not be suitable. The custom convex lens can be made from materials that resist heat, radiation, or corrosion.

Coating Requirements: To enhance transmittance or reduce reflection, various coatings can be applied to the lens surface, such as anti-reflective, reflective, or other functional coatings. The custom convex lens allows for coating options tailored to specific needs.

Non-Standard Sizes: Some scenarios require non-standard lens sizes, including extremely large or small diameters. The custom convex lens can be manufactured to precise dimensional requirements.

High Precision Requirements: In high-precision optical systems, the surface quality and optical accuracy of the lens are critical. The custom convex lens can be produced using high-precision machining and testing to achieve optimal surface smoothness, form accuracy, and optical performance.

Customization Process of the Plano Convex Lens

Requirement Analysis: The process begins by defining the application, optical performance targets, size specifications, material preferences, and coating needs. This information forms the basis for customization.

Optical Design: Based on the requirements, optical engineers design the plano convex lens, determining key parameters such as radius of curvature, focal length, and material, and verify the design using optical simulation software.

Material Selection: Depending on the operating environment and optical demands, appropriate materials are selected. Common options include BK7, fused silica, and calcium fluoride; specialized cases may require infrared or ultraviolet materials.

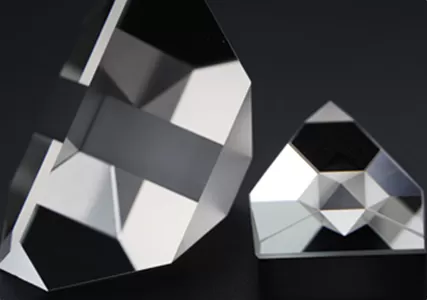

Machining and Polishing: The manufacturing process involves rough grinding, fine grinding, and polishing to ensure the surface quality and shape accuracy meet the design criteria. High-precision machining often utilizes CNC equipment and advanced polishing tools.

Coating: As needed, optical coatings are applied to the lens surface. Coating quality depends on strict control of layer thickness and uniformity to ensure reliable optical performance.

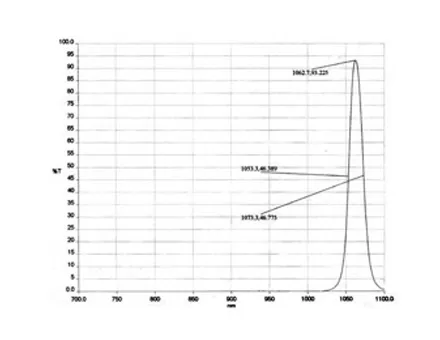

Inspection and Acceptance: After the custom convex lens is completed, it undergoes rigorous testing, including focal length verification, surface accuracy inspection, and transmittance measurement, to confirm compliance with design standards. Clients may review test reports for final approval.

The plano convex lens plays a vital role in optical systems. Its customized production can meet the specific needs of diverse applications. Through accurate optical design, material selection, machining, and inspection, the custom convex lens delivers outstanding performance, making it suitable for use in laser technologies, imaging systems, lighting equipment, and precision instruments. As optical technologies continue to advance, the custom convex lens will play an increasingly important role in enabling optical systems to achieve greater accuracy and efficiency.

EN

EN