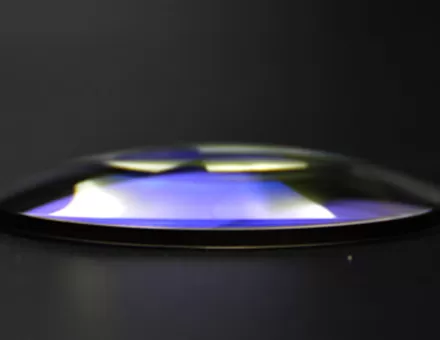

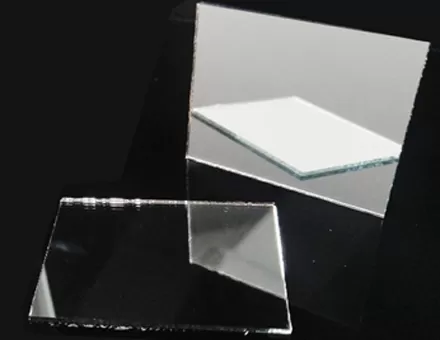

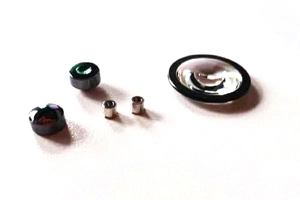

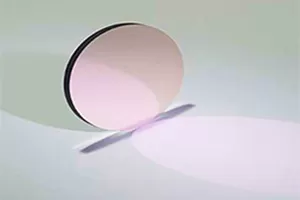

In the application of infrared thermal sensors, when choosing silicon window sheet materials (CZ monocrystalline silicon or FZ monocrystalline silicon), the following key factors need to be comprehensively considered:

1. Infrared transmission characteristics

CZ silicon (Czoidal method) : It contains oxygen (~10¹⁸ cm⁻³) and carbon impurities, which may introduce absorption peaks in the infrared band (especially in the mid-wave infrared of 3-5μm), reducing the transmittance.

FZ silicon (suspension zone melting method) : It has extremely high purity (impurities <10¹⁶ cm⁻³), extremely low oxygen/carbon content, and a higher transmittance in the 1-7μm range (especially with a significant advantage in the 3-5μm band), making it suitable for wide-band infrared applications.

2. Application scenario requirements

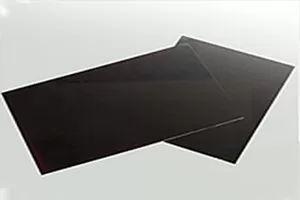

Short-wave infrared (1-3μm) : CZ silicon is sufficient and has a lower cost.

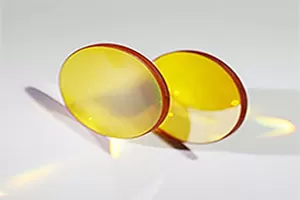

In the long wave infrared (3-12 microns) : better FZ silicon, but attention should be given to the cutoff wavelength of the silicon is about 1.1 mu m, long wave need to switch to other material (such as germanium, zinc selenide).

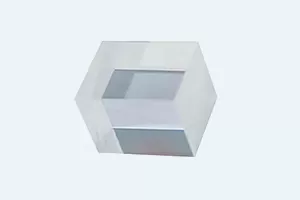

3. Other performance comparisons

Mechanical strength: The two are comparable. Silicon has a high hardness, but its brittleness needs to be noted.

Thermal stability: CZ silicon oxygen impurities may be more heat stress, but FZ silicon higher purity, high temperature performance is more stable.

The cost and size: CZ silicon cost is low and the preparation of large size (> 200 mm), FZ silicon prices are high and size is usually < 150 mm.

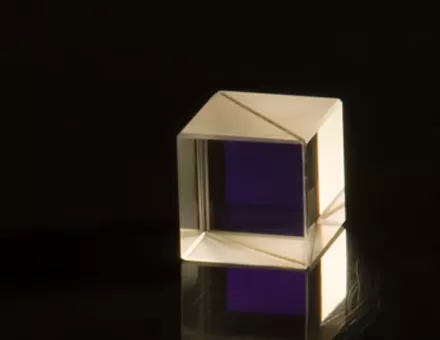

4. - coating of coating and surface processing, such as the SiO ₂, Ge) can promote transmittance, but more pure and FZ silicon for basal coating effect is better.

Conclusion and suggestions

Prioritize FZ silicon: If the sensor's operating band includes 3-5μm or extremely high transmittance is required, and the budget allows.

Optional CZ silicon: if only for short wave infrared or cost sensitive scenarios, absorbing impurities need to ensure that does not affect performance.

For > 7 microns long wave infrared, silicon is not applicable, should be considered germanium (Ge) or zinc sulfide (ZnS) administered etc. When making an actual choice, a comprehensive assessment should be made in combination with specific wavelength requirements, budget and supplier parameters (such as resistivity, crystal orientation, etc.).

EN

EN