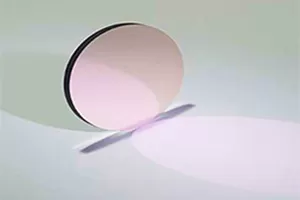

In the field of optical engineering, the choice of material often defines the limits of technology. Sapphire lenses, not carved from natural gemstones but made from synthetic single-crystal

aluminum oxide (α-Al₂ O₃ ), have become indispensable optical components in numerous

high-end and extreme applications. Thanks to their unparalleled physical and chemical properties —exceptional hardness, broad spectral transmission, outstanding thermal stability, and chemical

inertness—they safeguard the precise transmission of light, from the smartphones in our hands

to spacecraft exploring the depths of space.

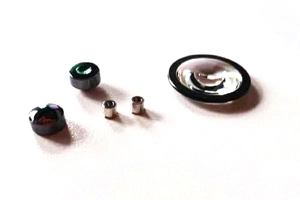

I. Consumer Electronics: The Durable Armor for Everyday Technology

In consumer electronics, the most well-known application of sapphire lenses is as camera covers

for smartphones and watch crystals for high-end smartwatches. With a Mohs hardness of 9, second only to diamond, they effectively resist daily scratches and abrasions, maintaining imaging

clarity over time. Furthermore, they are used as protective windows for under-display ultrasonic

fingerprint sensors, offering ultimate protection with minimal interference to the sensing signal.

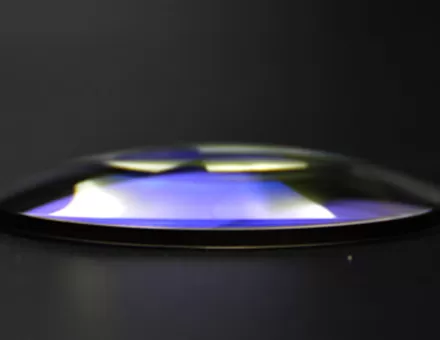

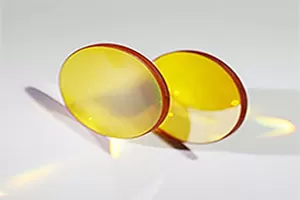

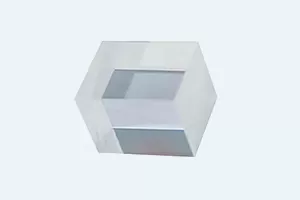

II. Industry & Lasers: The Resilient Core in High-Power Environments

In industrial settings, sapphire lenses are the ideal choice for handling high-power lasers. Particularly in CO ₂ lasers (wavelength 10.6 μ m), they are used as output windows and

focusing lenses. Compared to traditional zinc selenide (ZnSe) materials, sapphire offers higher

thermal conductivity and a higher laser-induced damage threshold (LIDT), enabling it to

withstand kilowatt-level laser power while being more wear-resistant and having a longer

lifespan. In semiconductor manufacturing and high-temperature industrial monitoring, sapphire

viewports withstand plasma erosion and temperatures exceeding a thousand degrees Celsius, ensuring precise process control.

III. Aerospace & Defense: The Reliable Vanguard Facing Extreme Challenges

In aerospace and defense, reliability is paramount. Sapphire is used to manufacture missile

infrared seeker domes. It not only transmits infrared radiation but also withstands aerodynamic

heating and particle erosion generated during supersonic flight. On satellites, it serves as a

window for optical systems, resistant to extreme temperature variations, vacuum radiation, and

atomic oxygen corrosion in space. Moreover, military night vision and targeting devices

incorporate sapphire as protective lenses to meet rigorous military standards.

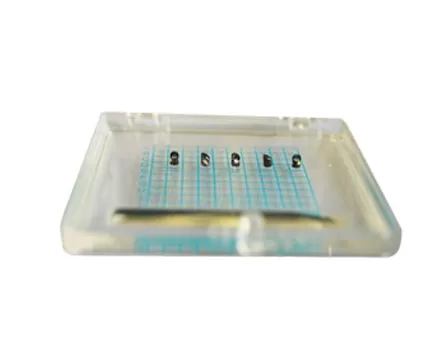

IV. Medical & Scientific Research: The Pure Eye of Precision Instruments

Medical equipment demands high standards of cleanliness and chemical stability. Sapphire lenses

are an excellent material for the output windows of medical laser devices (e.g., ophthalmic YAG

lasers). They can endure high-energy laser pulses and repeated autoclaving. In endoscopes, they

are used as front-end protective lenses, offering corrosion resistance and biocompatibility. At theforefront of research, from viewports for deep-sea submersibles capable of withstanding

pressure at 10,000-meter depths, to radiation-resistant sight glasses for nuclear reactors, and

X-ray windows for synchrotron radiation facilities, sapphire plays a critical role in the most

demanding scientific environments.

The application history of sapphire lenses is a microcosm of humanity's continuous push against

technological boundaries. They have transitioned from luxury items to standard components in

high-tech equipment. As manufacturing processes advance and costs optimize, the application

fields of sapphire lenses will undoubtedly expand further, continuing to serve as the most reliable

"transparent armor" for human vision in both known and unknown extreme environments.

EN

EN