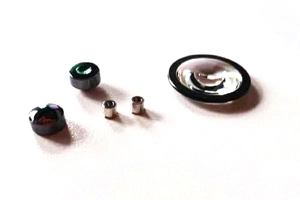

A very small lens is called a micro lens. They generally have a diameter of less than a millimeter (mm) and are often as small as 10 micrometers (µm). The first micro lenses were fabricated for use in microscopes in the 17th century. Now, micro lens arrays are still used for microscopes, as well as for many other applications, such as cell phone cameras, photocopiers, and 3D displays. They can even be found in nature, from simple structures to gather light for photosynthesis in leaves, to compound eyes in insects.

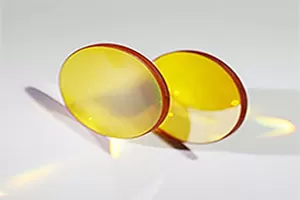

The small size of the micro lens means that a simple design is often best for optical quality, but sometimes optical diffraction, the bending of waves around an obstacle, at the lens’s small features leads to unwanted effects. A typical micro lens has one plane surface and one spherical convex surface to refract the light. Because micro-lenses are so small, the substrate, the underlying layer, that supports the lens is usually thicker. This extra thickness has to considered in the design of this type of precision optical products. Aspherical surfaces are used for more sophisticated lenses, and others may use several layers of optical material to reach a higher level of performance.

Another type of micro lens has two parallel flat planes, and the varying refractive index across the lens causes the act of focusing. These planes are known as gradient-index (GRIN) lenses. Some micro-lenses attain focus action by using both a variation in the refractive index and the surface shape. Micro-Fresnel lenses are a type of micro lens that focuses light by refracting it with a set of concentric curved surfaces. These lenses can be fabricated to be very thin and lightweight.

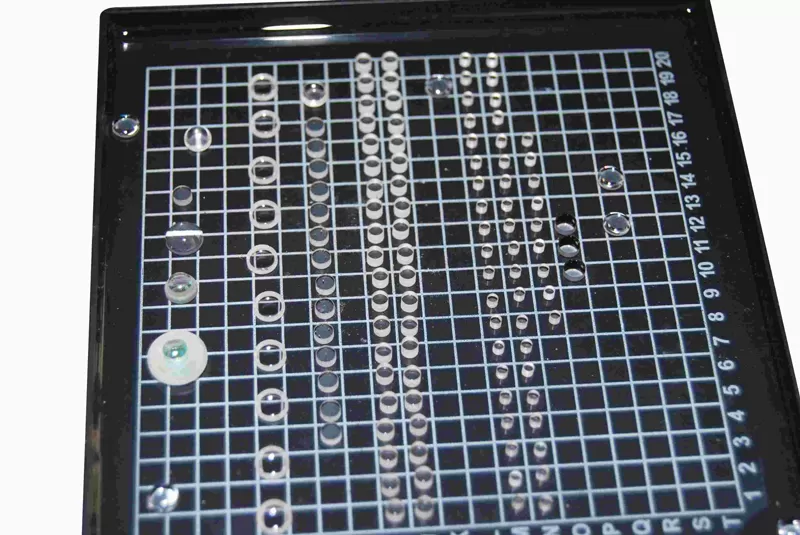

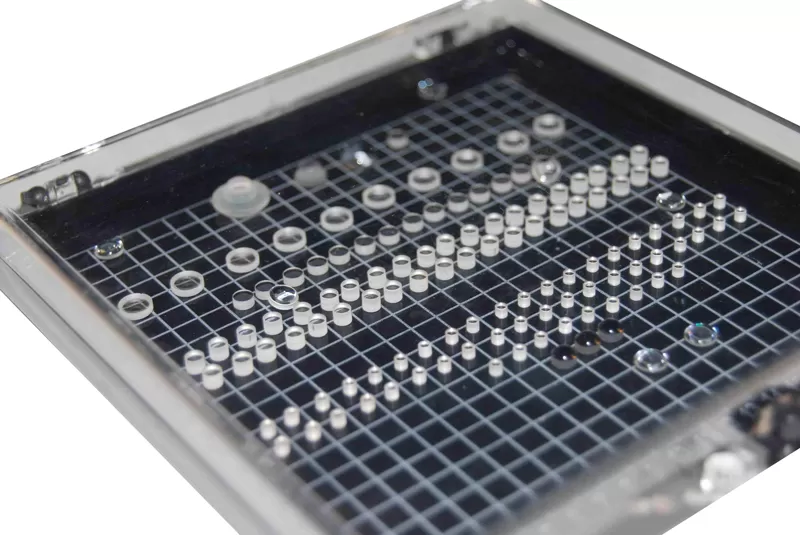

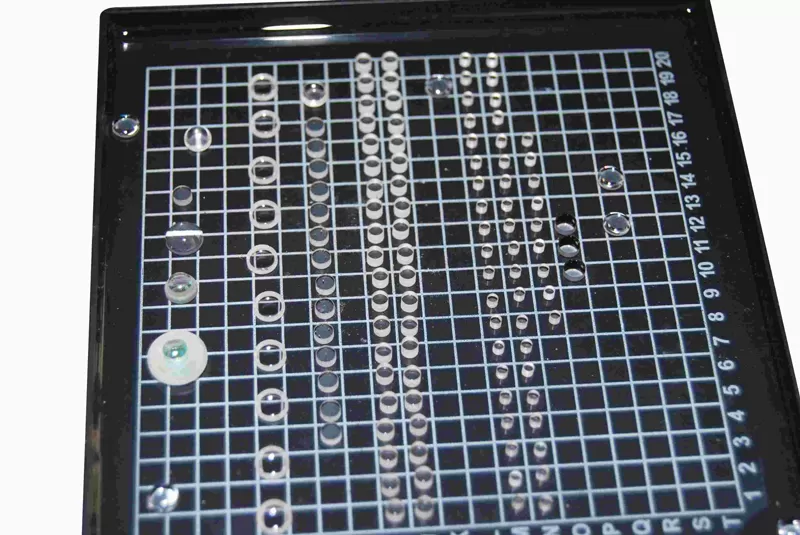

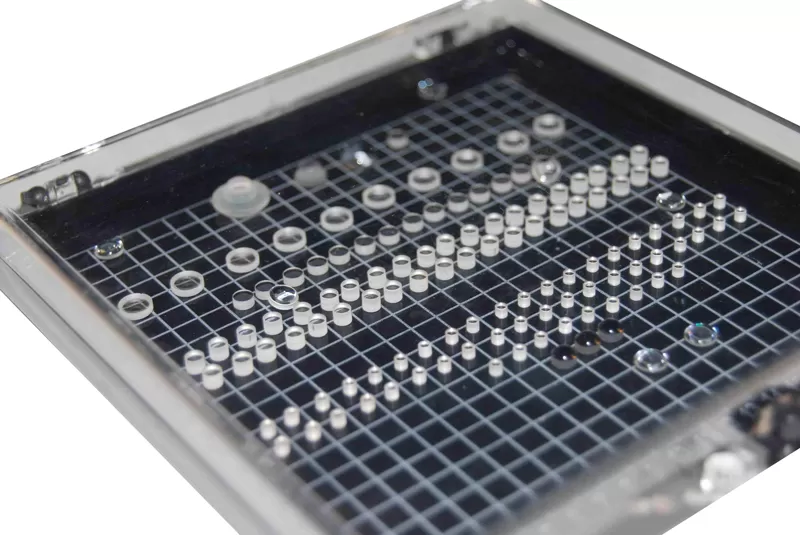

Micro-lens arrays provided by optical mirror manufacturers contain multiple micro lenses that are formed in either a one-dimensional or two-dimensional array on a supporting substrate. The separate lenses have circular apertures and are arranged in a hexagonal array to reach maximum coverage of the substrate. There are gaps between the lenses, but making the micro-lenses with non-circular apertures can reduce the gaps. With optical sensor arrays, the tiny lens systems focus and concentrate the light onto the photo-diode surface, so that it does not land on non-photosensitive areas of the pixel device.

Single micro lenses are used to pair light to optical fibers while micro lens arrays are often used to increase the light collection efficiency of charged couple device (CCD) arrays. The arrays collect and focus light onto the photosensitive areas of the CCD.

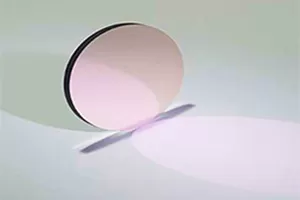

Micro lens arrays are also used as a way to focus light in some digital projectors. Projectors use liquid-crystal displays (LCDs), flat-panel displays that use the light-modulating properties of liquid crystals combined with polarizers. The arrays focus light to the active areas used to generate the projected image. Various types of micro lenses act as concentrators for high-efficiency photo voltaics for electricity production. Photo voltaics is the conversion of light into electricity using what is known as the photovoltaic effect. The photovoltaic effect is the creation of an electric current in a material when it is exposed to light. It is a physical and chemical phenomenon.

Combinations of micro lens arrays have been designed with imaging properties, such as the ability to form an image that is not inverted, unlike conventional lenses. Micro lens arrays are also used in compact imaging devices for applications such as photocopiers and smartphone cameras.

In optical microscopes, two micro lens arrays create uniform illumination. Two micro lens arrays are placed into the illumination path of a microscope, achieving highly accurate imaging. Micro lenses are also used in 3D imaging and displays.

EN

EN