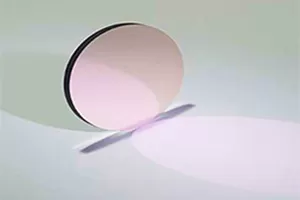

The difference between a cemented mirror and other glasses is that as a component of an optical system, it must meet the requirements of optical imaging. cemented cylindrical lens supplier believes that the determination of the quality of cemented lenses also includes some special and stricter indicators. There are the following requirements for glued mirrors:

1. High transparency

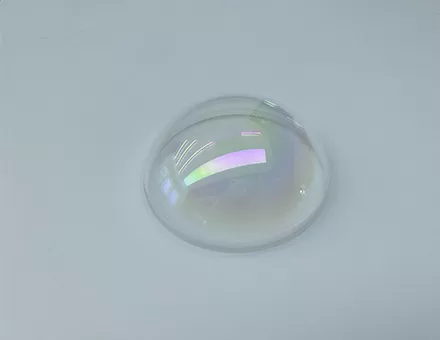

The brightness of the imaging of the optical system is proportional to the transparency of the glass. The transparency of a cemented mirror to light of a certain wavelength is expressed by the light absorption coefficient Kλ. After the light passes through a series of prisms and lenses, part of its energy is lost at the interface reflection of the optical parts and the other part is absorbed by the medium (glass) itself. The former increases with the refractive index of the glass. This value is very large for high refractive index glass, such as about 6% of the light reflection loss of a surface of heavy flint glass.

Therefore, for an optical system containing multiple thin lenses, the main way to improve the transmittance is to reduce the reflection loss on the lens surface, such as coating the surface antireflection coating. For large-sized optical parts such as the objective lens of an astronomical telescope, due to its large thickness, the transmittance of the optical system mainly depends on the light absorption coefficient of the glass itself. By improving the purity of the glass raw material and preventing any coloring impurities from being mixed in the whole process from batching to smelting, the light absorption coefficient of the glass can generally be less than 0.01 (that is, the glass with a thickness of 1 cm has a light transmittance greater than 99%).

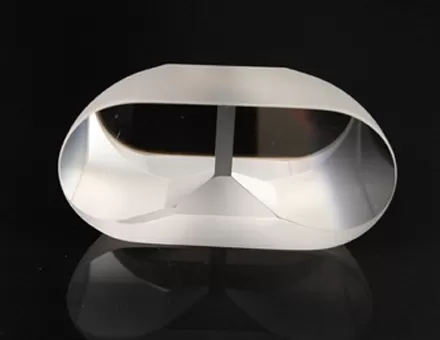

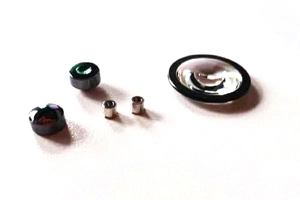

Achromatic Cemented Double Lens

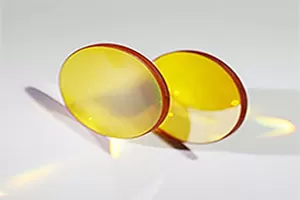

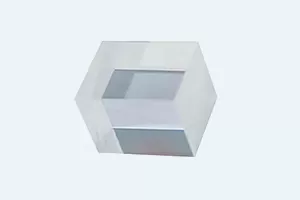

2. Specific optical constants and consistency of optical constants of the same batch of glass

Each type of cemented lens has a prescribed standard refractive index value for different wavelengths of light, which is used as the basis for the optical designer to design the optical system. Therefore, the optical constant of the cemented lens produced by the factory must be within a certain tolerance range of these values, otherwise the actual imaging quality will be inconsistent with the expected results during design and affect the quality of the optical instrument. At the same time, because the same batch of instruments are often manufactured with the same batch of cemented lenses, in order to facilitate the unified calibration of the instruments, the allowable deviation of the refractive index of the same batch of glass is more strict than their deviation from the standard value.

In achromatic cemented double lenses, it is more important to pay attention to the application and design of hollow cemented lenses (because in the curtain wall, the glass occupies a much larger area than the aluminum alloy frame). If 10 + 12A + 10 insulating glass is used, the heat transfer coefficient K is about 3.0W / (m2K), and the heat transfer coefficient is nearly 1/2 lower than that of single-layer glass, which can greatly reduce energy consumption. In the case of relatively high performance requirements, insulating glass should be used. If the insulating glass is filled with inert gas, its K value can be reduced to 1.3W / (m2K).

Under the condition that the cross-section of the aluminum alloy profile is unchanged, the insulating glass of different thickness is assembled by changing the size of the heat insulation strip and the rubber strip, so as to achieve different insulation design requirements for different regions, different types of buildings, Ask the owner to choose. The use of thermal insulation curtain wall can play a very good energy saving and noise reduction effect.

Compared with ordinary single-layer glass, it saves about 25% ~ 50% of energy consumption and reduces noise by about 30db ~ 40db. Node design of dynamic curtain wall Dynamic curtain wall is a new type of energy-saving curtain wall and a new development of curtain wall technology. According to its structure, it can be divided into two types: "closed internal circulation system" and natural ventilation "open external circulation system". The former requires forced ventilation through the motor, so the overall energy saving level is not high; the latter through natural ventilation, so the energy saving effect is more obvious.

EN

EN