Ⅰ. Advanced measurement and evaluation of precision optical components

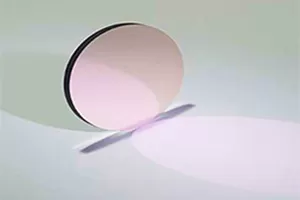

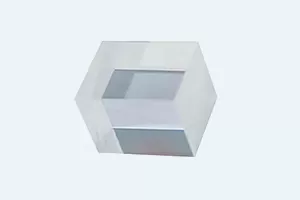

This paper mainly introduces the detection principle and technology of precision optical components comprehensively and comprehensively, tracks the principle and application of the latest science and technology cutting-edge technology, closely follows the actual application requirements, and studies the key technologies in the detection process. Firstly, the quality evaluation criteria of optical components are introduced in detail, including surface shape error evaluation criteria, sub-surface damage evaluation, and optical components uniformity evaluation.

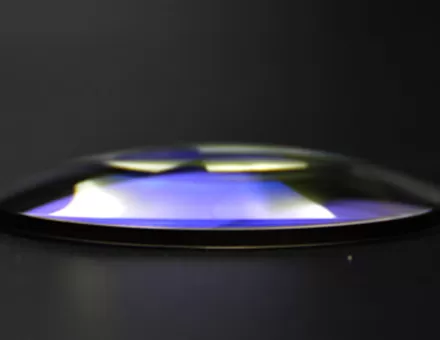

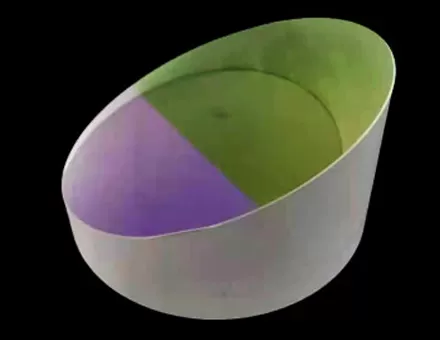

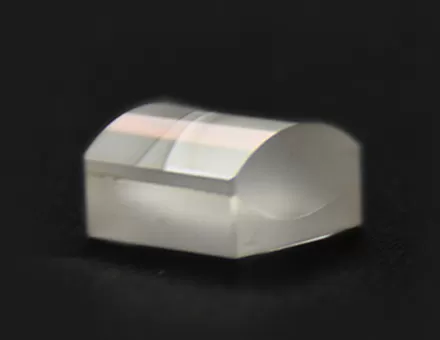

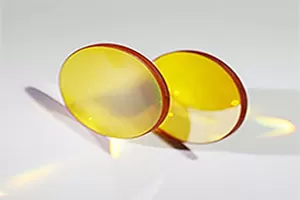

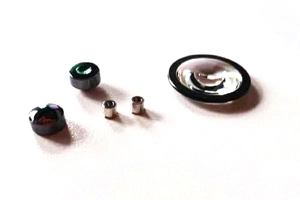

The principle of interference detection and cutting-edge international technology is introduced, especially phase-shift interference technology, dynamic interference technology, etc. For the aspheric surface detection by compensation method, the optical compensator and computer-generated holographic compensator are mainly introduced, and the design principle, manufacturing technology, and assembly and adjustment technology are presented and analyzed in detail. Then, the principle of sub-aperture stitching technology is introduced, the key stitching algorithms are studied in detail, the measurement platform is built, and it has been well applied in practical engineering.

Ⅱ. Surface quality inspection solutions of precision optical components

The surface quality detection process of precision optical components is very cumbersome and full of uncertainty. The surface finish has a very important impact on the device's performance. Therefore, we need to explore the corresponding detection technology. The research and development team of Ecootik deeply studied the surface defects of general optical elements by means of scanning electron microscopy. Aiming at the point and line defects of precision optical components, a composite optical system is independently developed to detect optical elements' dust, pitting, and scratches. At the same time, sample vehicles suitable for different sizes and scenes have also been developed. The special algorithm scheme is embedded into the international testing standards, which can help the national glass material enterprises to carry out accurate, standardized, and scientific surface quality testing.

It has a special optical system for transparent optical glass, combined with a machine vision imaging scene, high imaging contrast, clear defects, standardized differentiation of surface defect types, and finish grades. The high-precision standard version made by the micro nano machining method helps the system and algorithm standardize the data, and the measurement results are objective and accurate. It is equipped with dust removal module to meet different detection scenarios.

EN

EN