Ⅰ. About optical lenses

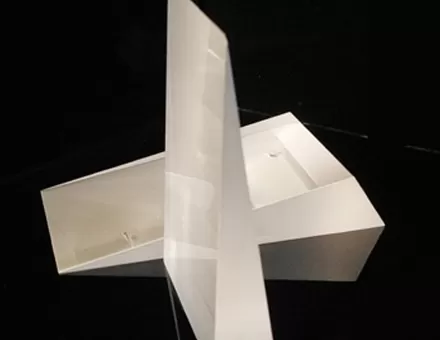

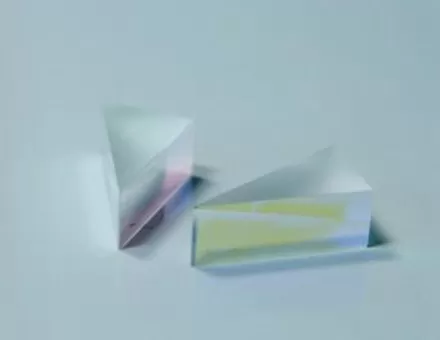

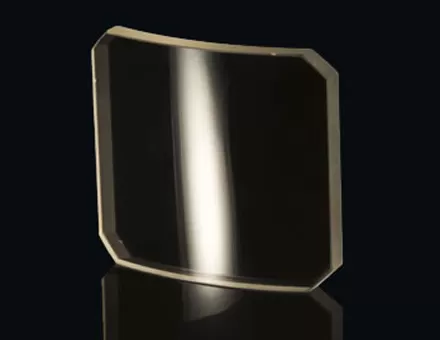

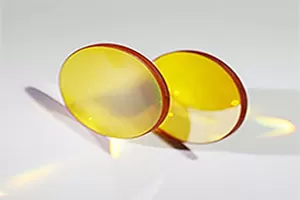

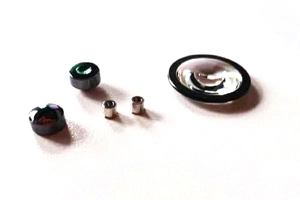

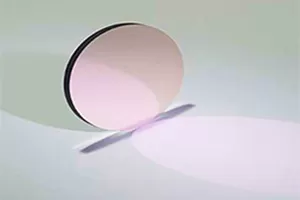

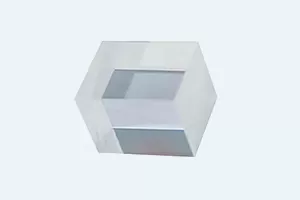

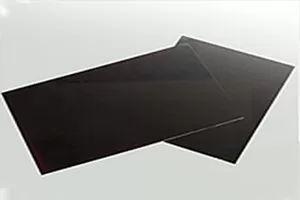

Optical lenses are lenses manufactured by optics. One of typical lenses are cylindrical optical lenses. Optical lenses have specific optical properties such as refractive index, dispersion, transmittance, spectral transmittance, and light absorption. They are lenses with uniform optical properties. Optical lenses can change the direction of light propagation and change the relative spectral distribution of ultraviolet, visible, or infrared light. Optical lenses in a narrow sense refer to colorless optical lenses; in a broad sense, they also include colored optical lenses, laser lenses, quartz optical lenses, anti-radiation lenses, ultraviolet and infrared optical lenses, fiber optics lenses, acousto-optic lenses, magneto-optical lenses, and photochromic lens. Optical lenses can manufacture lenses, prisms, mirrors, and windows in optical instruments. Components composed of optical lenses are key elements in optical instruments.

Ⅱ. The origin of optical lenses

The first lenses used to make lenses were lumps on ordinary windows or wine bottles. The shape resembled a crown, and the name or crown lens was derived from this. The lenses were highly uneven and had a lot of foam. In addition to crown lenses, there is another crushed stone lens with higher lead content. In 1790, Frenchman Pierre Louis Junaid discovered that mixing lens paste can produce uniform lenses. In 1884, Ernst Abbe and Otto Schott of Zeiss founded the Schott lens factory in Jena, Germany. Within a few years, they developed dozens of optical lenses. The barium crown lenses with high refractive index Invention is one of the essential achievements of SCHOTT Lens Factory.

Optical lenses are made by mixing high purity silicon, boron, sodium, potassium, zinc, lead, magnesium, calcium, barium, and other oxides according to a specific formula. Melt it at high temperature in a platinum crucible, stir evenly with ultrasonic to remove bubbles, then slowly cool it down for a long time to avoid internal stress in the lens block. Optical instruments must measure the cooled lens block to check whether the purity, transparency, uniformity, refractive index, and dispersion rate meet the specifications. The qualified lens block is heated and forged to form an optical lens photo.

EN

EN