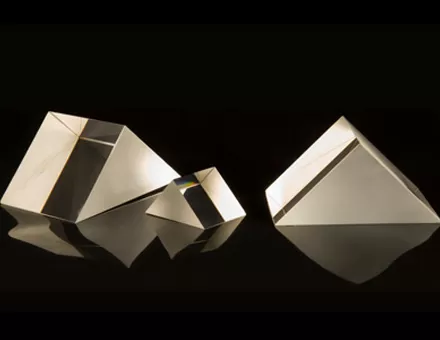

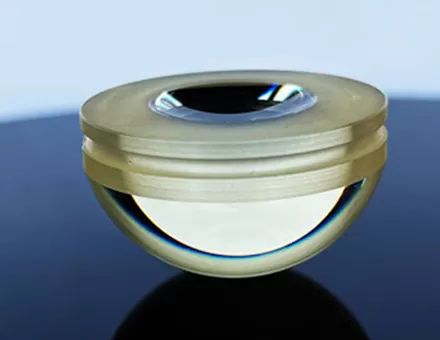

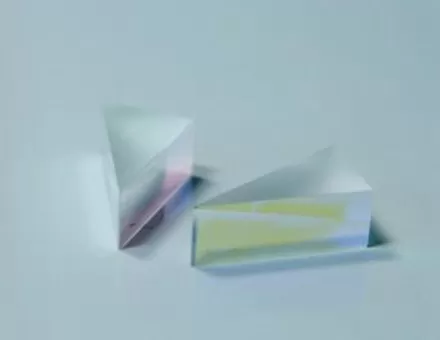

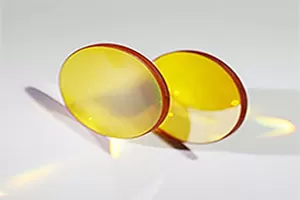

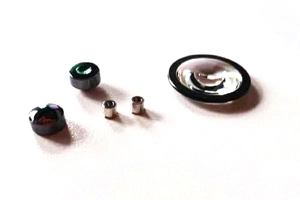

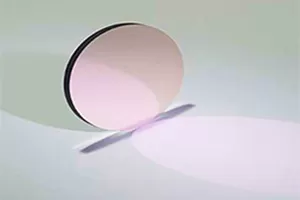

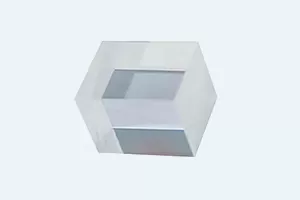

Off-axis Parabolic Mirrors (OAP) are a portion of parabolic mirrors that are off the center of symmetry of an axisymmetric paraboloid. Off-axis mirrors are one of the commonly used components for building terahertz and infrared light paths based on the geometry of a paraboloid, which can focus a collimated beam/collimated THz wave incident in parallel to a focal point, and can also convert terahertz or infrared light emitted from a point source into a beam transmitted in parallel.

Off-axis parabolic mirrors have the ability to focus collimated light without introducing spherical aberration. When a collimated beam is incident perpendicular to the bottom of the mirror substrate, the reflected light converges at the focal point. By placing a point light source at the focal point, a collimated beam is obtained. The angle between the focused beam and the collimated beam is called the off-axis angle, and off-axis parabolic mirrors with different off-axis angles can be obtained by intercepting different intervals of the parent paraboloid.

The base material of off-axis parabolic mirrors is generally aluminum metal, and precision metal tools are used for surface machining, so off-axis mirrors all work on the principle of reflection, which eliminates the phase delay and absorption loss of the transmitting optical element. The surface roughness of off-axis mirrors has a significant impact on their performance, and typically have a <50Å or <100Å RMS surface roughness.

Off-axis parabolic mirrors are widely used in astronomical observation optics, spectroscopic detection, astronomical telescope systems, sighting devices, beam expanders, infrared systems, concentrating solar power systems, projection systems, and transmitting/detecting equipment. Compared to lenses, the use of off axis parabolic mirror does not produce spherical aberration, chromatic aberration, and does not introduce phase delays and absorption losses, making them ideal for femtosecond laser, infrared, and terahertz applications.

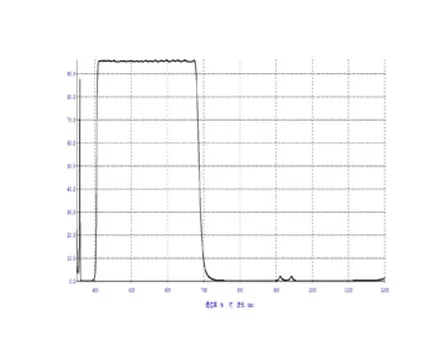

In addition, off-axis parabolic mirrors are available with different coating types to meet different usage requirements. For example, UV enhanced aluminum coating (250~450nm), silver coating with protective layer (450nm~20μm), aluminum coating with protective layer (450nm~20μm), or gold coating with or without protective layer (800nm~20μm) can be selected.

Translated with DeepL.com (free version)

EN

EN