The laser beam splitter is abbreviated as the beam splitter, and its similar products also have a diffractive multi-line array DOE. That is, a 1*M line array is obtained instead of a 1*M dot array. The length of the line array can be designed by the diffraction pattern of the DOE surface. Laser beam splitters are used in many industries and research. Typical fields are laser scribing (such as scribing in solar cells or panels), laser cutting, laser displays, medical or cosmetic applications (such as skincare), 3D Point generators, infrared depth detectors, optical fibers, and so on.

Ⅰ. The operating principles of the laser beam splitter

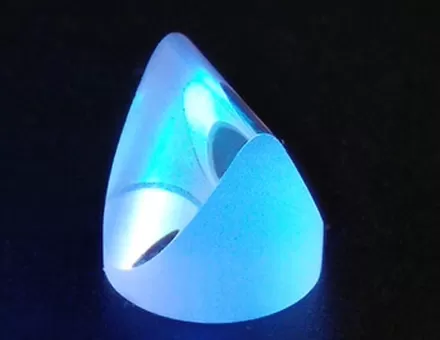

The collimated incident laser beam passes through the beam splitter DOE, and the output beam will be emitted at a specific separation angle. This specific separation angle is designed according to the requirements, and the separation angle is highly accurate, with an error of less than 0.03 mRad. The beam separation is designed for the far-field so that as the beam gradually separates after passing through the DOE, the output beam becomes clearer.For a laser beam splitter with an odd number of output beams, the separation angle is the angle between the 0order beam and the +1order beam, and the 0-order beam is the required output beam and is activated.

For the beam splitter with an even number of output beams, the separation angle is the angle between the +1order beam and the -1 order beam. At this time, the 0order beam is not the required beam and is not activated.

Ⅱ. Precautions and limitations of the laser beam splitter

1. In the configuration of the laser beam splitter that outputs dual beams, due to physical limitations, the power efficiency can reach nearly 80%, while the power efficiency of the two-stage etched multi-beam (number of output beam)2) configuration can reach nearly 85%, And the beam splitter with multi-step etching can reach nearly 95%. The remaining power is distributed among other unwanted order beams.

2. Multi-level etching is only worthwhile if the minimum feature size of the diffraction pattern is not that small. If it is too small, manufacturing tolerances may reduce the efficiency level to close to the binary level. The minimum feature size is a function of the laser beam splitter's total divergence angle and wavelength.

3. The energy distribution can be the uniform energy distribution between multiple output beams or the uneven energy distribution between beams meeting the application requirements.

4. Generally, in the initial test stage of the project, users may want to use standard products whose design wavelength is not the same as the actual application wavelength. In this case, the expected performance of the actual wavelength can be provided to the user because for a specific model of the laser beam splitter, the energy of different diffraction orders will be redistributed after the wavelength is changed.

5. For a single-mode laser, the minimum input beam diameter is determined by the design parameters of DOE specification. In the case of an odd number of beam splitting points, the minimum incident beam diameter is at least three times the number of cycles in DOE; If the laser beam splitter has an even number of issues, the incident beam is at least 1.5 times of this size.

EN

EN